Title 08

DEPARTMENT OF NATURAL RESOURCES

Subtitle 18 BOATING—SPEED LIMITS AND

OPERATION OF VESSELS

08.18.01 General

Authority: Natural Resources Article, §8-704, Annotated Code of

Maryland

Notice of Proposed Action

[25-060-P]

The Secretary of Natural Resources proposes to amend Regulation .08

under COMAR 08.18.01 Boating—Speed Limits and Operation of Vessels.

Statement of Purpose

The purpose of this action is to update the section of the Patapsco

River designated as Class III white water. The current section described in

regulation is from Woodstock (Md. Rte. 125) to Glen Artney (Patapsco State

Park—Old Dam). The reference to an “old dam” in Glen Artney is not completely

clear; additionally, all of the Patapsco River dams have been removed, except

for Daniels Dam, which is much further upstream than Glen Artney. After review

of the area, a physical landmark was chosen as the endpoint to make it easy for

users to understand. The proposed action designates Gun Road as the new

endpoint. Gun Road crosses the river and is an easy landmark. Updating the

endpoint of the Class III section of the Patapsco River will properly apprise

paddlers of potential dangers.

Estimate of Economic Impact

The proposed action has no economic impact.

Economic Impact on Small Businesses

The proposed action has minimal or no economic impact on small

businesses.

Impact on Individuals with Disabilities

The proposed action has no impact on individuals with disabilities.

Opportunity for Public Comment

Comments may be sent to White

Water Regulation, Regulatory Staff, Maryland Department of Natural Resources

Fishing and Boating Services, 580 Taylor Avenue

E-4, Annapolis, MD 21401, or call 410-260-8300, or email to [email protected]

or complete the comment form at

dnr.maryland.gov/boating/Pages/regulations/changes_boating.aspx#wwss. Comments

will be accepted through August 11, 2025. A public hearing has not been

scheduled.

.08 Boating on White Water Portions of

Designated Stream Segments.

A.—C. (text unchanged)

D. The Department of

Natural Resources is designating the following stream segments for purposes of

this boating safety regulation only, and intends no determination whether there

is any right of public access to, navigation along, landing along, or egress

from, any of these designated stream segments. This regulation does not apply

to the use of vessels on non-white water portions of designated stream segments

for any purpose other than access to white water. The designated stream

segments are:

(1) Class III—stream

segments:

(a)—(g) (text unchanged)

(h) Patapsco

River—Woodstock (Md. Rte. 125) to [Glen Artney (Patapsco State Park—Old

Dam)] Gun Road;

(i)—(m) (text unchanged)

(2)—(4) (text unchanged)

E.—F. (text unchanged)

JOSH KURTZ

Secretary of Natural

Resources

Title 10

MARYLAND DEPARTMENT OF HEALTH

Subtitle 32 BOARD OF PHYSICIANS

10.32.06 Licensure of

Polysomnographic Technologists

Authority: Health Occupations Article, §§1-213, 1-221,

1-606, 14-205, and 14-5C-01—14-5C-23, Annotated Code of Maryland

Notice of Proposed Action

[25-123-P]

The Secretary of Health proposes to amend Regulations .02, .04,

.06, .07, and .09—13 under COMAR 10.32.06 Licensure of

Polysomnographic Technologists. This

action was considered at public meetings on December 4, 2019 and January 29,

2020, notice of which was given by

publication on the Board’s Website at https://www.mbp.state.md.us from November

15, 2019 through December 4, 2019 and January 13, 2020 through January 29, 2020

respectively pursuant to General Provisions Article, §3-302(c), Annotated Code

of Maryland.

Statement of Purpose

The purpose of this proposed action is to update existing

regulations for clarity, consistency with other Board regulations, and to

reflect statutory changes pursuant to 2017 sunset legislation: Chapter

218: “State Board of Physicians and

Allied Health Advisory Committees—Sunset Extension and Program Evaluation.”

Specifically, the proposal includes but is not limited to:

(1) Restructuring of COMAR 10.32.06.04 to clarify the pathways to

licensure. A definition of the phrase

“enrolled in a sleep technologist program” has been added to support the

proposed revisions to Regulation .04;

(2) Adding a statement to Regulation .09 about non-refundable fees

for consistency with other Board regulations;

(3) Removing duplicative language from Regulation .11 regarding

reporting requirements;

(4) Changing the “Board” to a “disciplinary panel” in Regulations

.10, .12, and .13 pursuant to 2017 sunset legislation;

(5) Renaming Regulation .12 to reflect all topics covered;

(6) Revising certain section titles under Regulation .12; and

(7) Other revisions or technical corrections as needed.

Estimate of Economic Impact

The proposed action has no economic impact.

Economic Impact on Small Businesses

The proposed action has minimal or no economic impact on small

businesses.

Impact on Individuals with Disabilities

The proposed action has no impact on individuals with disabilities.

Opportunity for Public Comment

Comments may be sent to Jordan Fisher Blotter, Director, Office of

Regulation and Policy Coordination, Maryland Department of Health, 201 West

Preston Street, Room 534 Baltimore, Maryland 21201, or call 410-767-0938, or

email to [email protected]. Comments will be accepted through August 11,

2025. A public hearing has not been scheduled.

.02 Definitions.

A. (text unchanged)

B. Terms Defined.

(1)—(8) (text unchanged)

(9) “Enrolled in a sleep technologist educational program” means

that a student has started the Accredited Sleep Technology Program self-study

online modules developed by the American Academy of Sleep Medicine but has not

completed the final self-study module.

[(9)] (10) "General supervision"

means supervision by a licensed physician who is available to give

immediately available direction, either in person, by telephone, or by

electronic means.

[(10)] (11)—[(15)] (16)

(text unchanged)

[(16)] (17) "Practice

polysomnography" means:

(a) (text unchanged)

(b) Using the data collected under [§B(15)(a)] §B(17)(a)

of this regulation for the purposes of assisting a licensed physician in the

diagnosis and treatment of sleep and wake disorders.

[(17)] (18)—[(19)] (20)

(text unchanged)

.04 Application for Initial Licensure as a Polysomnographic

Technologist.

A. An applicant shall:

(1)—(6) (text unchanged)

[(7) Provide documentation of one of the following:

(a) For those candidates applying for a license on or before

September 30, 2013:

(i) Passing the national certifying examination of the Board of

Registered Polysomnographic Technologists on or before September 30, 2013; and

(ii) Certification by the Board of Registered Polysomnographic

Technologists as a registered polysomnographic technologist at the time of

application;

(b) Graduation from a polysomnographic educational program that is

accredited by the Commission on Accreditation of Allied Health Education

Programs;

(c) Both of the following:

(i) Graduation from a respiratory care educational program that is

accredited by the Commission on Accreditation of Allied Health Education

Programs; and

(ii) Completion of the Committee on Accreditation for Respiratory

Care’s curriculum for a polysomnography certificate that is accredited by the

Commission on Accreditation of Allied Health Education Programs;

(d) Both of the following:

(i) Graduation from an electroneurodiagnostic technology

educational program that is accredited by the Commission on Accreditation of

Allied Health Education Programs; and

(ii) Completion of an add-on track in polysomnography for

electroneurodiagnostic technologists that is accredited by the Commission on

Accreditation of Allied Health Education Programs; or

(e) Each of the following:

(i) Graduation from a sleep technologist educational program

accredited by the American Academy of Sleep Medicine;

(ii) Proof of meeting core competencies in the 3 years preceding

the application as assessed by a sleep technologist credentialed as a

Registered Polysomnographic Technologist, a sleep technologist with national

certification approved by the Board, or a physician who is either

board-eligible or board-certified in sleep medicine by the American Board of

Sleep Medicine, American Board of Medical Specialties, or American Osteopathic

Association;

(iii) A letter of attestation for completion of clinical hours and

competencies from a physician who is either board-eligible or board-certified

in sleep medicine by the American Board of Sleep Medicine, American Board of

Medical Specialties, or American Osteopathic Association where the applicant

practiced; and

(iv) The requirements listed in §B of this regulation; and

(8) Provide documentation of licensure, certification, or

registration from all states where the applicant has ever held a license,

certificate, or registration in any health profession.

B. If an applicant satisfies the requirements of §A(7) of this

regulation by completing the requirements of §A(7)(e) of this regulation, the

applicant shall provide proof of completion of a minimum of 546 hours of

clinical experience in the 3 years preceding licensure application as either:

(1) A student supervised by a sleep technologist credentialed as a

Registered Polysomnographic Technologist or a sleep technologist with national

certification approved by the Board at an American Academy of Sleep Medicine

accredited sleep laboratory or sleep laboratory accredited by The Joint

Commission; or

(2) A sleep technologist with a current, active, unrestricted

license in another state or is otherwise recognized and has practiced as a

sleep technologist in another state who has:

(a) Full-time practice experience as a sleep technologist in

another state at an American Academy of Sleep Medicine accredited sleep

laboratory or sleep laboratory accredited by The Joint Commission for a minimum

of 6 months in the 3 years preceding the application; and

(b) Maintained an average of 10 continuing education units per year

for the last 2 years.]

(7) Provide documentation of licensure, certification, or

registration from all states where the applicant has ever held a license,

certificate, or registration in any health profession; and

(8) Meet the requirements of §B of this regulation.

B. An applicant shall meet the requirements of one of the

following pathways to licensure:

(1) Graduation from a polysomnographic educational program that

is accredited by the Commission on Accreditation of Allied Health Education

Programs;

(2) In regard to a respiratory care educational program:

(a) Graduation from a respiratory care educational program that

is accredited by the Commission on Accreditation of Allied Health Education

Programs; and

(b) Completion of the Committee on Accreditation for Respiratory

Care’s curriculum for a polysomnography certificate that is accredited by the

Commission on Accreditation of Allied Health Education Programs;

(3) In regard to an electroneurodiagnostic technology

educational program:

(a) Graduation from an electroneurodiagnostic technology

educational program that is accredited by the Commission on Accreditation of

Allied Health Education Programs; and

(b) Completion of an add-on track in polysomnography for

electroneurodiagnostic technologists that is accredited by the Commission on

Accreditation of Allied Health Education Programs; or

(4) In regard to a sleep technologist educational program,

completion of the requirements of §C of this regulation.

C. An applicant who has

graduated from a sleep technologist education program accredited by the

American Academy of Sleep Medicine shall:

(1) Provide proof of meeting core competencies in the 3 years

preceding the date of the submission of the licensure application as assessed

by a sleep technologist credentialed as a Registered Polysomnographic

Technologist, a sleep technologist with national certification approved by the

Board, or a physician who is either board-eligible or board-certified in sleep

medicine by the American Board of Sleep Medicine, American Board of Medical

Specialties, or American Osteopathic Association;

(2) Provide a letter of attestation for completion of clinical

hours and competencies from a physician who is either board-eligible or

board-certified in sleep medicine by the American Board of Sleep Medicine,

American Board of Medical Specialties, or American Osteopathic Association

where the applicant practiced; and

(3) Provide proof of completion of a minimum of 546 hours of

clinical experience in the 3 years preceding the date of the submission of the

licensure application as either:

(a) A student enrolled in a sleep technologist educational

program supervised at a sleep laboratory accredited by the American Academy of

Sleep Medicine or The Joint Commission by:

(i) A sleep technologist credentialed as a Registered

Polysomnographic Technologist;

(ii) A sleep technologist with national certification approved

by the Board; or

(iii) A licensed physician who is either board-eligible or

board-certified in sleep medicine by the American Board of Sleep Medicine,

American Board of Medical Specialties, or American Osteopathic Association; or

(b) A sleep technologist with a current, active, unrestricted

license in another state or is otherwise recognized and has practiced as a

sleep technologist in another state who has:

(i) Full-time practice experience as a sleep technologist in

another state at a sleep laboratory accredited by the American Academy of Sleep

Medicine or The Joint Commission for a minimum of 6 months in the 3 years

preceding the date of the submission of the licensure application; and

(ii) Completed at least 30 hours of approved continuing

education in the 3 years preceding the date of the submission of the licensure

application.

.06 Identification as Polysomnographic Technologist; Notice of

Name or Address Change.

A. A licensed polysomnographic technologist shall wear an

identification tag or a badge [which identifies that individual as]

displaying in readily visible type that the individual is a licensed

polysomnographic technologist.

B. An individual may not identify himself or herself as a

polysomnographic technologist unless the individual is licensed by the Board.

[B.] C. (text unchanged)

.07 Renewal and Reinstatement.

A. Renewal.

(1) The Board may not renew a license until the Comptroller of

Maryland has verified that the individual has paid all undisputed taxes and

unemployment insurance contributions, or arranged for [repayment, as

required by COMAR 10.31.02.] repayment.

(2) An individual who has been licensed by the Board as a

polysomnographic technologist may renew the license on or before the date

specified by the Board by:

(a)—(b) (text unchanged)

(c) Attesting to the completion of at least 20 hours of approved

continuing education, earned during the 2-year period preceding the expiration

of the license, as specified in Regulation .08 of this chapter; and

(d) (text unchanged)

B. (text unchanged)

.09 Fees.

A. The following fees are applicable to polysomnographic

technologists:

[A. Initial license fees:

(1) Initial licensure application fee — $200; and

(2) Maryland Health Care Commission (MHCC) fee — As determined by

MHCC under COMAR 10.25.03;

B. License renewal fees:

(1) License renewal fee — $150; and

(2) Maryland Health Care Commission (MHCC) fee — As determined by

MHCC under COMAR 10.25.03;

C. Reinstatement fees:

(1) Reinstatement fee — $200; and

(2) Maryland Health Care Commission (MHCC) fee — As determined by

MHCC under COMAR 10.25.03;

D. Written verification of licensure fee — $25;

E. Replacement of registration card — $25; and

F. Replacement of wall license — $75.]

(1) Initial licensure application fee — $200;

(2) License renewal fees:

(a) License renewal fee — $150; and

(b) Maryland Health Care Commission (MHCC) fee — As determined

by MHCC in accordance with COMAR 10.25.02;

(3) Reinstatement fee — $200; and

(4) Written verification of licensure fee — $25.

B. Fees paid to the Board

are non-refundable.

.10 Prohibited Conduct.

A. Subject to the hearing provisions of Health Occupations Article,

§14-405, Annotated Code of Maryland, and in accordance with COMAR 10.32.02,

[the Board] a disciplinary panel may deny a license to any

applicant, reprimand any licensee, place any licensee on probation, or suspend

or revoke a license if the applicant or licensee:

(1)—(28) (text unchanged)

B. Crimes of Moral Turpitude.

(1) Proceedings for crimes of moral turpitude under Health

Occupations Article, §14-5C-17(c), Annotated Code of Maryland, shall be held in

accordance with COMAR [10.32.02.04] 10.32.02.07.

(2) On the filing of certified docket entries with the Board by the

Office of the Attorney General, [the Board] a disciplinary

panel shall order the suspension of a license if the licensee is convicted

of, or pleads guilty or nolo contendere with respect to, a crime involving

moral turpitude, whether or not any appeal or other proceeding is pending to

have the conviction or plea set aside.

(3) After completion of the appellate process, if the conviction

has not been reversed or the plea has not been set aside with respect to a

crime involving moral turpitude, the [Board] disciplinary

panel shall order the revocation of a license on the certification by the

Office of the Attorney General.

.11 Required Reports.

[A. Except as provided in §B, C, or F of this regulation,

hospitals, related institutions, alternative health systems as defined in

Health Occupations Article, §1-401, Annotated Code of Maryland, and employers

shall file with the Board a report that the hospital, related institution,

alternative health system, or employer limited, reduced, otherwise changed, or

terminated any licensed polysomnographic technologist for any reason that might

be grounds for disciplinary action under Health Occupations Article, §14-5C-17,

Annotated Code of Maryland, or any regulation in this chapter.

B. If the action taken by a hospital, related institution,

alternative health system, or employer under §A of this regulation relates to

alcohol or drug impairment, the hospital, related institution, alternative

health system, or employer is not required to report the polysomnographic

technologist to the Board if:

(1) The hospital, related institution, alternative health system,

or employer knows that the licensed polysomnographic technologist is:

(a) In an alcohol or drug treatment program that is accredited by

the Joint Commission on the Accreditation of Health Care Organizations or is

certified by the Department; or

(b) Under the care of a health care practitioner who is competent

and capable of dealing with alcoholism and drug abuse;

(2) The hospital, related institution, alternative health system,

or employer is able to verify that the licensed polysomnographic technologist

remains in the treatment program until discharge; and

(3) The action or condition of the licensed polysomnographic

technologist has not caused injury to an individual while the technologist is

practicing as a licensed polysomnographic technologist.

C. If a licensed polysomnographic technologist enters, or is

considering entering, an alcohol or drug treatment program that is accredited

by the Joint Commission on Accreditation of Health Care Organizations or that

is certified by the Department, the licensed polysomnographic technologist

shall notify the hospital, related institution, alternative health system, or

employer of the licensed polysomnographic technologist's decision to enter the

treatment program.

D. If the licensed polysomnographic technologist fails to provide

the notice required under §C of this regulation, and the hospital, related

institution, alternative health system, or employer learns that the licensed

polysomnographic technologist has entered a treatment program, the hospital,

related institution, alternative health system, or employer shall report to the

Board that the licensed polysomnographic technologist has entered a treatment

program and has failed to provide the required notice.

E. Noncompliance.

(1) If the licensed polysomnographic technologist is found to be

noncompliant with the treatment program's policies and procedures while in the

treatment program, the treatment program shall notify the hospital, related

institution, alternative health system, or employer of the licensed

polysomnographic technologist's noncompliance.

(2) On receipt of the notification required under §E(1) of this

regulation, the hospital, related institution, alternative health system, or

employer of the licensed polysomnographic technologist shall report the

licensed polysomnographic technologist's noncompliance to the Board.

F. A individual is not required under this regulation to make any

report that would be in violation of any federal or state law, rule, or

regulation concerning the confidentiality of alcohol and drug abuse patient

records.

G. The hospital, related institution, alternative health system, or

employer shall submit a required report within 10 days of any action described

in this regulation.

H. A report made under this regulation is not subject to subpoena

or discovery in a civil action other than a proceeding arising out of a hearing

and decision of the Board under Health Occupations Article, Title 14, Annotated

Code of Maryland.]

A reporting entity, as defined in COMAR 10.32.22.02, shall file

all required reports in accordance with Health Occupations Article, §14-5C-18,

Annotated Code of Maryland, and COMAR 10.32.22.

.12 [Penalties.] Penalties,

Fines, and Sanctions.

A. (text unchanged)

B. An individual who violates any provision of Health Occupations

Article, Title 14, Subtitle 5C, Annotated Code of Maryland, or any regulation

in this chapter, is subject to a civil fine of not more than $5,000 to be

levied by the Board or a disciplinary panel.

C. (text unchanged)

D. Employment of an Unlicensed Polysomnography Practitioner.

(1) A person who violates Health Occupations Article, §14-5C-22.1,

Annotated Code of Maryland, is subject to a civil fine of not more than $5,000 to

be levied by the Board.

(2) (text unchanged)

E. [Failure to Make a Required Report.

(1) The Board may impose a fine up to $1,000 for a hospital,

related institution, alternative health system, or employer who fails to make a

report to the Board required by Regulation .11 of this chapter.

(2) The Board shall deposit any funds collected under §E(1) of this

regulation into the State’s General Fund.] The Board may impose a

fine up to $1,000 for a reporting entity, as defined in COMAR 10.32.22.02, that

fails to make a report to the Board required by COMAR 10.32.22.

F. General Application of Sanctioning Guidelines.

(1) Sections F and G of this regulation and Regulation [.16A

and B] .13 of this chapter do not apply to offenses for which a

mandatory sanction is set by statute or regulation.

(2) Except as provided in §G of this regulation, for violations of

the sections of the Maryland Polysomnography Act listed in the sanctioning

guidelines, [the Board] a disciplinary panel shall impose

a sanction not less severe than the minimum listed in the sanctioning

guidelines nor more severe than the maximum listed in the sanctioning

guidelines for each offense.

(3) (text unchanged)

(4) The [Board] disciplinary panel may impose

more than one sanction, provided that the most severe sanction neither exceeds

the maximum nor is less than the minimum sanction permitted in the chart.

(5) (text unchanged)

(6) If a licensee has violated more than one ground for discipline

as set out in the sanctioning guidelines:

(a) (text unchanged)

(b) The [Board] disciplinary panel may impose

concurrent sanctions based on other grounds violated.

(7) Notwithstanding the sanctioning guidelines set forth in

Regulation .13 of this chapter, in order to resolve a pending disciplinary

action, the [Board] disciplinary panel and the licensee

may agree to a surrender of license or a consent order with terms and sanction

agreed to by the [Board] disciplinary panel, the

administrative prosecutor, and the licensee.

(8) Depending on the facts and circumstances of each case, and to

the extent that the facts and circumstances apply, the [Board] disciplinary

panel may consider the aggravating and mitigating factors set out in §G(4)

and (5) of this regulation and may in its discretion determine, based on those

factors, that an exception should be made and that the sanction in a particular

case should fall outside the range of sanctions listed in the sanctioning

guidelines.

(9) If the [Board] disciplinary panel imposes

a sanction that departs from the sanctioning guidelines as set forth in

Regulation .13 of this chapter, the [Board] disciplinary panel

shall state its reasons for doing so in its final decision and order.

G. Aggravating and Mitigating Factors.

(1) Depending on the facts and circumstances of each case, and to

the extent that the facts and circumstances apply, the [Board] disciplinary

panel may consider the aggravating and mitigating factors set out in [§H(4)

and (5)] §G(4)—(5) of this regulation and may in its discretion

determine, based on those factors, that an exception should be made and that

the sanction in a particular case should fall outside the range of sanctions

listed in the sanctioning guidelines.

(2) Nothing in this regulation requires the [Board] disciplinary

panel or an Administrative Law Judge to make findings of fact with respect

to any of these factors.

(3) The existence of one or more of these factors does not impose

on the [Board] disciplinary panel or an Administrative Law

Judge any requirement to articulate its reasoning for not exercising its

discretion to impose a sanction outside of the range of sanctions set out in

the sanctioning guidelines.

(4)—(5) (text unchanged)

(6) A departure from the sanctioning guidelines set forth in

Regulation .13 of this chapter is not a ground for any hearing or appeal of a [Board]

disciplinary panel action.

H. Offenses Related to [Continuing Medical Education

Credits.] Continuing Education Requirements.

(1) If a licensee has submitted an application claiming the

completion of continuing [medical] education credits and the

licensee fails to document the completion of such continuing [medical]

education credits when audited by the Board, the licensee may be charged under

one or more of the following, as appropriate:

(a)—(c) (text unchanged)

(2) Upon a finding of a violation, the [Board] disciplinary

panel may impose any discipline authorized under Health Occupations

Article, §14-5C-17, Annotated Code of Maryland, and the sanctioning guidelines.

I. Payment of Fines Imposed by the Board or a Disciplinary Panel.

(1) An individual shall pay to the Board any fine imposed [under]

pursuant to this regulation within 15 calendar days of the date of the

order, unless the order specifies otherwise.

(2) Filing an appeal under State Government Article, §10-222,

Annotated Code of Maryland, does not stay payment of a fine imposed [by

the Board] pursuant to this regulation.

(3) If an individual fails to pay, in whole or in part, a fine

imposed [by the Board] pursuant to this regulation, the Board may

not restore, reinstate, or renew a license until the fine has been paid in

full.

(4) In its discretion, the Board may refer all cases of delinquent

payment to the Central Collection Unit of the State Department of Budget

and Management to institute and maintain proceedings to ensure an

individual’s prompt payment.

.13 Sanctioning Guidelines for Polysomnographic Technologists.

A. Subject to provisions of Regulation .12F and G of this chapter, [the

Board] a disciplinary panel may impose sanctions as outlined in

§B of this regulation on polysomnographic technologists for violations of

Health Occupations Article, §14-5C-17(a), Annotated Code of Maryland.

B. (text unchanged)

LAURA HERRERA SCOTT

Secretary of Health

Subtitle 34 BOARD OF PHARMACY

10.34.04 Transfer and

Outsourcing of Prescriptions and Prescription Orders

Authority: Health Occupations Article, §12-205 (a)(3)(ii),

Annotated Code of Maryland

Notice of Proposed Action

[25-117-P]

The Acting Secretary of Health proposes to amend Regulations .01

and .03, adopt new Regulation .06, and recodify existing

Regulations .06—.09 to be Regulations .07—.10 under COMAR

10.34.04 Transfer and Outsourcing of Prescriptions and Prescription Orders. This action was considered by the Board of

Pharmacy at a public meeting held on January 15, 2025, notice of which was

given by publication on the Board’s website at

https://health.maryland.gov/pharmacy/Pages/index.aspx pursuant to General Provisions Article,

§3–302(c), Annotated Code of Maryland.

Statement of Purpose

The purpose of this action is to:

(1) Clarify and update policies and procedures;

(2) Clarify and update standards for quality assurance; and

(3) Update required reference materials.

Estimate of Economic Impact

The proposed action has no economic impact.

Economic Impact on Small Businesses

The proposed action has minimal or no economic impact on small

businesses.

Impact on Individuals with Disabilities

The proposed action has no impact on individuals with disabilities.

Opportunity for Public Comment

Comments may be sent to Jordan Fisher Blotter, Director, Office of

Regulation and Policy Coordination, Maryland Department of Health, 201 West

Preston Street, Room 534 Baltimore, Maryland 21201, or call 410-767-0938, or

email to [email protected]. Comments will be accepted through August 11,

2025. A public hearing has not been scheduled.

.01 Scope.

This

chapter governs the:

A.

Transfer of prescriptions for non-controlled

dangerous substances between pharmacies;

B.—C.

(text unchanged)

.03 Permanent Transfer of a Prescription Between Pharmacies.

A

pharmacist from a primary pharmacy may permanently transfer a prescription

order to a secondary pharmacy to be dispensed to a specific patient if [:

A.

The prescription is lawfully refillable;

B.

The prescription is not for a Schedule II controlled dangerous substance noted

in Criminal Law Article, Title 5, Subtitle 4, Annotated Code of Maryland;

C.

The] the pharmacist

transferring the prescription from the primary pharmacy indicates on the

prescription, within the prescription computer database and within any

appropriate other records used for dispensing:

[(1)]A.—[(5)]E. (text unchanged)

.06 Transfers of Prescription for

Controlled Dangerous Substances.

A pharmacist may transfer a

prescription for a controlled dangerous substance in accordance with federal

law.

RYAN B. MORAN, DRPH, MHSA

Acting Secretary of

Health

10.34.07 Pharmacy Equipment

Authority: Health Occupations Article, §§12-205 and 12-403,

Annotated Code of Maryland

Notice of Proposed Action

[25-126-P]

The Acting Secretary of Health proposes to amend Regulation .01-1

under COMAR 10.34.07 Pharmacy Equipment.

This action was considered by the Board of Pharmacy at a public meeting

held on January 15, 2025, notice of which was given by publication on the

Board’s website at https://health.maryland.gov/pharmacy/Pages/index.aspx

pursuant to General Provisions Article, §3–302(c), Annotated Code of Maryland.

Statement of Purpose

The purpose of this action is to:

(1) Clarify and update policies and procedures;

(2) Clarify and update standards for quality assurance; and

(3) Update required reference materials.

Estimate of Economic Impact

The proposed action has no economic impact.

Economic Impact on Small Businesses

The proposed action has minimal or no economic impact on small

businesses.

Impact on Individuals with Disabilities

The proposed action has no impact on individuals with disabilities.

Opportunity for Public Comment

Comments may be sent to Jordan Fisher Blotter, Director, Office of

Regulation and Policy Coordination, Maryland Department of Health, 201 West

Preston Street, Room 534 Baltimore, Maryland 21201, or call 410-767-0938, or

email to [email protected]. Comments will be accepted through August 11,

2025. A public hearing has not been scheduled.

.01-1 Equipment.

A

pharmacy shall have the following equipment to carry out the practice of

pharmacy in Maryland:

A. If

applicable, a Class A prescription balance and weights, or a prescription

balance with equivalent or superior sensitivity to a Class A prescription

balance; and

B. A

refrigerator and freezer, if applicable, solely for the storage of drugs

requiring refrigeration, with a thermometer or a temperature monitoring device[; and].

[C. A freezer, if applicable.]

RYAN B. MORAN, DRPH, MHSA

Acting Secretary of

Health

Subtitle

42 BOARD OF SOCIAL WORK EXAMINERS

10.42.02 Social Work Practice

Authority: Health

Occupations Article, §19-205, Annotated Code of Maryland

Notice of Proposed

Action

[25-112-P]

The Acting Secretary of

Health proposes to amend Regulation .02 and adopt new Regulation .06

under COMAR 10.42.02 Social Work Practice. This action was considered by the Board of

Social Work Examiners at a public meeting held on December 13, 2024, notice of

which was given by publication on the Board’s website at

health.maryland.gov/bswe/Pages/default.aspx pursuant to General Provisions

Article, §3–302(c), Annotated Code of Maryland.

Statement of Purpose

The purpose of this action

is to clarify certain definitions and establish a new regulation for private

practice.

Estimate of Economic Impact

The proposed action has no economic impact.

Economic Impact on Small Businesses

The proposed action has minimal or no economic impact on small

businesses.

Impact on Individuals with Disabilities

The proposed action has no impact on individuals with disabilities.

Opportunity for Public Comment

Comments may be sent to Jordan Fisher Blotter, Director, Office of

Regulation and Policy Coordination, Maryland Department of Health, 201 West

Preston Street, Room 534 Baltimore, Maryland 21201, or call 410-767-0938, or

email to [email protected]. Comments will be accepted through August 11,

2025. A public hearing has not been scheduled.

.02 Definitions.

A. (text unchanged)

B. Terms Defined.

(1)—(7) (text unchanged)

(8) Independent Practice.

(a) "Independent clinical practice" means

the practice of licensed clinical social work without the requirement of

social work supervision.

(b) “Independent non-clinical practice” means the practice of

licensed non-clinical social work without the requirement of social work

supervision.

(9)—(11) (text unchanged)

(12) “Non-clinical social work” means assisting individuals,

groups, families, or communities in accessing critical services, locating

resources, negotiating and advocating on behalf of clients, community

organizing, teaching, researching, developing and analyzing policy, and other

non-clinical activities.

[(12)] (13)—[(20)] (21)

(text unchanged)

.06 Private Practice.

A. An LMSW, Board-approved for independent practice, may not

practice clinical social work without supervision in accordance with §B of this

regulation.

B. Supervision Requirements.

(1) An LMSW shall only practice clinical social work under the

supervision of a Board-approved LCSW-C supervisor for clinical practice

employed by the same practice as the LMSW.

(2) An LMSW or LBSW may not practice clinical social work under

the supervision of a:

(a) Psychiatrist;

(b) Psychologist; or

(c) Licensed clinical professional counselor.

C. An LCSW-C supervisor shall:

(1) Ensure the LMSW is:

(a) Properly licensed; and

(b) Knowledgeable of the laws and regulations as set forth in

Health Occupations Article, Title 19, Annotated Code of Maryland and this

subtitle;

(2) Assess the:

(a) LMSW’s:

(i) Knowledge;

(ii) Skills;

(iii) Experience;

(iv) Competence; and

(v) Training; and

(b) Client’s needs;

(3) Assign clients to the LMSW based on the assessment conducted

in §C(2) of this regulation;

(4) Participate in the initial intake and diagnostic assessment

of all clients served by the LMSW until the LMSW is determined to be competent;

(5) Be considered as having a professional/therapeutic

practitioner relationship with the clients served by the LMSW, as evidenced in

documents, such as invoices and client agreements, indicating the name of the

supervising LCSW-C;

(6) Maintain full responsibility for the LMSW’s practice and

professional conduct, including any disciplinary actions;

(7) Monitor and ensure effective and ethical services to

clients;

(8) Maintain full records of practice and communication, which

clearly establishes the LMSW is a supervisee and not an independent

practitioner; and

(8) Comply with the requirements and responsibilities set forth

in COMAR 10.42.08.

D. An LMSW supervisee shall practice within the scope of

practice set forth in Regulation .03B of this chapter.

E. LMSW supervisees may not:

(1) Receive payment directly from the client or client’s

insurance carrier;

(2) Be the owner or in charge of the practice;

(3) Be the lessor in a co-lease or sublease arrangement of

office space where the practice is based or delivered;

(4) Advertise for clients or patients without clearly

identifying the LMSW’s supervisor; and

(5) Directly or indirectly solicit clients or patients for:

(a) Themselves; or

(b) The supervising LCSW-C.

RYAN B. MORAN, DRPH, MHSA

Acting Secretary of

Health

Subtitle 65 BOARD OF MASSAGE THERAPY

EXAMINERS

Notice of Proposed Action

[25-105-P]

The Secretary of Health proposes to:

(1) Amend Regulation .02 under COMAR 10.65.07 Fees; and

(2) Adopt new Regulations .01—.05 under a new chapter, COMAR

10.65.12 Handheld Tools.

This action was considered by the Board of Massage Therapy

Examiners at a public meeting held on October 23, 2024, notice of which was

given by publication on the Board’s website at

health.maryland.gov/massage/Pages/home.aspx pursuant to General Provisions

Article, §3–302(c), Annotated Code of Maryland.

Statement of Purpose

The purpose of this action is to

add a new chapter for handheld tools pursuant to Ch. 788, Acts of 2024,

and a one-time registration fee for licensees trained and qualified for usage.

Estimate of Economic Impact

I. Summary of Economic Impact. The handheld tool

registration fee is for licensees who are trained/qualified for usage. This is

a new requirement and therefore the number of licensees who will register is

unknown. Nevertheless, while the full economic impact is unknown, the impact is

unlikely to be significant as the proposed fee is a one-time registration fee

of $100.

II. Types of Economic Impact.

|

Impacted Entity

|

Revenue

(R+/R-)

Expenditure

(E+/E-)

|

Magnitude

|

|

A. On issuing agency:

|

|

|

|

Board of Massage Therapy

Examiners

|

(R+)

|

Indeterminable

|

|

B. On other State agencies:

|

NONE

|

|

|

C. On local governments:

|

NONE

|

|

|

|

Benefit

(+)

Cost

(-)

|

Magnitude

|

|

D. On regulated industries or

trade groups:

|

|

|

|

Licensees of the Board of Massage Therapy

|

(-)

|

Indeterminable

|

|

E. On other industries or

trade groups:

|

NONE

|

|

|

F. Direct and indirect

effects on public:

|

NONE

|

|

III. Assumptions. (Identified by Impact Letter and Number

from Section II.)

A. The number of licensees who will register is unknown. The

proposed fee is a one-time registration fee of $100.

D. See A above.

Economic Impact on Small Businesses

The proposed action has minimal or no economic impact on small

businesses.

Impact on Individuals with Disabilities

The proposed action has no impact on individuals with disabilities.

Opportunity for Public Comment

Comments may be sent to Jordan Fisher Blotter, Director, Office of

Regulation and Policy Coordination, Maryland Department of Health, 201 West

Preston Street, Room 534 Baltimore, Maryland 21201, or call 410-767-0938, or

email to [email protected]. Comments will be accepted through August 11,

2025. A public hearing has not been scheduled.

10.65.07 Fees

Authority: Health Occupations Article, §§6-206 and 6-207, Annotated

Code of Maryland

.02 Fees for Massage Therapy Licensure and Registration.

The following fees are established by the Board and are

non-refundable:

A.—Q. (text unchanged)

R. Paper copy of laws and regulations . . . $40[.];

and

S. Handheld tool one-time registration fee. . . $100.

10.65.12 Handheld Tools

Authority: Health Occupations Article, §§6-101(f)(2)(ii) and

6-206(a)(1), Annotated Code of Maryland

.01 Scope.

Pursuant to Health Occupations Article, §6-101(f)(2)(ii),

Annotated Code of Maryland, this chapter establishes standards for the use of

instrument-assisted soft tissue manipulation techniques, also known as handheld

tools, by a licensed massage therapist or a registered massage therapist.

.02 Definitions.

A. In this chapter, the following terms have the meanings

indicated.

B. Terms Defined.

(1) “Board” means the State Board of Massage Therapy Examiners.

(2) “Good standing” means that the Board has not:

(a) Reprimanded the licensee, suspended or revoked the license

or registration of the licensee; or

(b) Placed the licensee on probation within 5 years before the

submission of a handheld tool registration application.

(3) Handheld Tool.

(a) “Handheld tool” means an instrument that is used by a

licensee in the practice of massage therapy to enhance or imitate manual

techniques.

(b) “Handheld tool” includes a:

(i) Mechanized vibration instrument; or

(ii) Muscle-scraping tool.

(c) “Handheld tool” does not include a tool exclusively used for

protective self-care, including a:

(i) Thumb-saver tool;

(ii) Trigger point tool; or

(iii) Still point inducer.

(4) “Licensee” means, unless the context requires otherwise, a

licensed massage therapist or a registered massage practitioner authorized by

the Board to practice massage therapy.

(5) “National Certification Board of Therapeutic Massage and

Bodyworkers (NCBTMB)” means the National Certification Board of Therapeutic

Massage and Bodyworkers.

(6) “Practice massage therapy” has the meaning stated in Health

Occupations Article, §6-101(f), Annotated Code of Maryland.

.03 Registration Required.

A. The Board shall register a licensee as qualified to use

handheld tools in the State if the licensee:

(1) Is in good standing as defined in Regulation .02 of this

chapter;

(2) Submits adequate documentary evidence that the licensee

meets the education and training requirements set forth in Regulation .04 of

this chapter;

(3) Submits an application for registration on the form provided

by the Board; and

(4) Pays the one-time registration fee as specified in COMAR

10.65.07.02.

B. A licensee may not use any handheld tool without first

registering as qualified with the Board in accordance with §A of this

regulation.

.04 Minimum Education and Training Requirements.

A. In order to be registered by the Board as qualified to use

handheld tools, a licensee shall meet the requirements of this regulation.

B. A licensee shall complete a minimum of 12 hours of

instruction in the following content areas:

(1) Philosophy and historical perspective of handheld tools and

massage therapy treatment;

(2) Indications, contra-indications, and qualifications for

handheld tools in the practice of massage therapy;

(3) Licensee and patient safety when using handheld tools;

(4) Case management and jurisprudence when using handheld tools;

(5) Recordkeeping, specifically detailing implementation and

specific location of instrument use; and

(6) The clinical use of muscle scraping and mechanized vibration

tools in the practice of massage therapy.

C. The instruction required by this regulation shall be approved

in advance by the Board or the NCBTMB.

D. Prior Instruction.

(1) The Board shall accept a continuing education course

completed before the effective date of this chapter, if the same course, in

substantially similar form, is sponsored by a continuing education provider

approved by the Board or the NCBTMB.

(2) Notwithstanding §D(1) of this regulation, the Board may not

accept a course completed before January 1, 2018.

E. The coursework required by this regulation shall be in

addition to the 750 contact hours of education required by Health Occupations

Article, §6-302, Annotated Code of Maryland.

.05 Standards of Practice.

A. A licensee registered to use handheld tools shall:

(1) Fully explain and demonstrate the use of the handheld tool

to the client in advance of the tool’s use;

(2) Obtain informed written consent specific to the handheld

tool and maintain that written consent within the client’s record;

(3) Utilize handheld tools in a manner consistent with the

standards set forth in the Maryland Occupational Safety and Health Act, Labor

and Employment Article, Title 5, Annotated Code of Maryland, and its associated

regulations;

(4) Document the use of handheld tool therapy in accordance with

COMAR 10.65.06;

(5) Be responsible for the ongoing evaluation, assessment, and

re-evaluation of client impairments;

(6) Only use handheld tools on parts of the body with

neuromuscular or musculoskeletal links to those impairments; and

(7) Maintain continuing competence for handheld tool usage.

B. Any violation of these standards of practice or of the

requirements of this chapter may subject the licensee

to discipline pursuant to Health Occupations Article,

§6-308, Annotated Code of Maryland.

LAURA HERRERA SCOTT

Secretary of Health

Title 11

DEPARTMENT OF TRANSPORTATION

Subtitle 14 MOTOR VEHICLE

ADMINISTRATION—VEHICLE INSPECTIONS

Notice of Proposed Action

[25-058-P]

The Administrator of the Motor Vehicle Administration and the

Department of State Police jointly propose to:

(1) Repeal existing Regulations .01—.18 and adopt new

Regulations .01—.16 under COMAR 11.14.01 General Inspection

Requirements and Provisions;

(2) Repeal existing Regulations .01—.26 and adopt new

Regulations .01—.29 under COMAR 11.14.02 Vehicle Inspection Standards;

(3) Repeal existing Regulations .01—.14 under COMAR

11.14.03 Safety Standards for Motorcycles;

(4) Repeal existing Regulations .01—.23 under COMAR

11.14.04 Safety Standards for Trucks, Truck Tractors, Commercial Buses, and

Type I School Vehicles;

(5) Repeal existing Regulations .01—.11 under COMAR

11.14.05 Safety Standards for Trailers; and

(6) Repeal existing Regulations .01—.07 under COMAR

11.14.06 Emissions Equipment Standards.

Statement of Purpose

The purpose of this action is to repeal the existing chapters of

regulations regarding the licensing of vehicle inspection stations, and the

registration of inspection mechanics, and adopt new chapters to address changes

in vehicle technologies, vehicle inspection test tools and equipment, and to

separate, organize, and clarify the existing regulations regarding vehicle

equipment safety inspection. The new proposed chapters remove unnecessary and

obsolete language, update references, address changes in automotive standards

and emerging technologies, and incorporate current policy and procedures for

the licensing and regulatory oversight of Maryland Vehicle Safety Inspection

program by the Maryland Department of State Police Automotive Safety

Enforcement Division (ASED).

This action also establishes the licensing of inspection mechanics

independent of an inspection station license. This will allow persons to be

examined and licensed as vehicle inspection mechanics prior to employment at

inspection stations and will facilitate the transfer of inspection mechanics

from one station to another without unnecessary delay and interruption of

employment.

In addition, the proposed new regulations make provision for the

inspection of vehicles which have been properly modified for operation by

persons with special needs. ASED will provide an examination of specially

modified vehicles and the related documentation at no cost to persons with

special needs. ASED personnel will then provide a form that identifies the

properly modified equipment, which will be presented to inspection stations and

inspection mechanics to allow vehicle safety inspections to be performed and

certified with certain authorized exemptions to regulated vehicle equipment.

Finally, the proposal addresses auxiliary equipment installed on

vehicles that potentially risk person, property, or environmental hazards which

is not currently regulated and makes provisions for current and emerging

automotive technologies for vehicle safety that are not currently regulated

such as supplemental restraint systems, anti-lock brakes and traction control,

and stability systems. eliminates requirements for obsolete or ineffective test

equipment and tools and allows the current test equipment and tools used in the

automotive industry to be approved for use during vehicle safety inspections.

Estimate of Economic Impact

I. Summary of Economic Impact. There is a positive economic

impact on the vehicle repair/service companies that are licensed inspection

stations in the Vehicle Safety Inspection Program and a positive impact on

members of the public.

II. Types of Economic Impact.

|

Impacted Entity

|

Revenue

(R+/R-)

Expenditure (E+/E-)

|

Magnitude

|

|

A. On issuing agency:

|

|

|

|

MVA

|

(E-)

|

None

|

|

B. On other State agencies:

|

|

|

|

No Impact

|

(E-)

|

None

|

|

C. On local governments:

|

|

|

|

None

|

(E-)

|

None

|

|

|

Benefit

(+)

Cost

(-)

|

Magnitude

|

|

D. On regulated industries or

trade groups:

|

|

|

|

Positive Impact

|

(+)

|

$2,500

|

|

E. On other industries or

trade groups:

|

|

|

|

None

|

(+)

|

0

|

|

F. Direct and indirect

effects on public:

|

|

|

|

Positive Impact

|

(+)

|

0

|

III. Assumptions. (Identified by Impact Letter and Number

from Section II.)

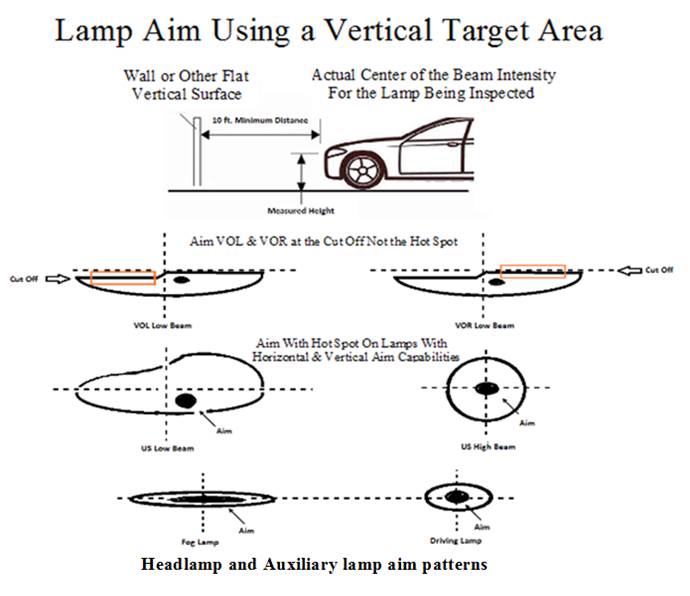

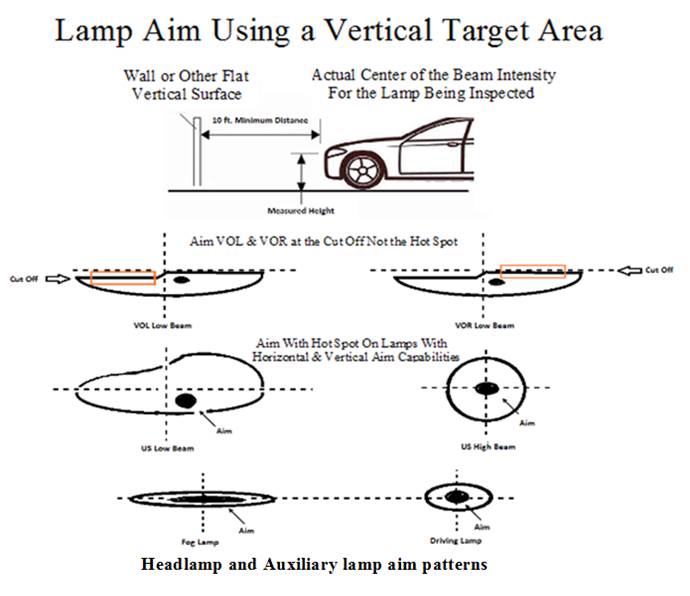

D. The implementation of the revised Vehicle Inspection Handbook,

COMAR Title 11 subtitle 14 will have a positive economic impact on the vehicle

repair/service companies that are licensed inspection stations in the Vehicle

Safety Inspection Program. The revised

regulations eliminate an expensive previously required tool, a headlight-aiming

machine, which saves the station between $1,500 and $2,500 depending on the

brand and model of tool they purchased.

The elimination of this tool provides for a quicker inspection process

that saves the station time and can increase their earning potential on a daily

basis. The stations will be required, as they currently are, to purchase the

new Vehicle Inspection Handbook, which has a cost of $50.00 plus $15.00 shipping

and handling.

F. There is a positive impact on members of the public as well, the

revised regulations have provisions to inspect and accommodate specialized and

or modified equipment installed in vehicles for persons with disabilities. Whether it is equipped for disabled

passengers and or disabled drivers.

Currently, there are no provisions to accommodate this equipment, and at

times the vehicles will need be converted back to a conventional vehicle for

inspection. This is cost-prohibitive.

An additional positive impact to the public in the revised

regulation is a provision to allow heavy-duty pickup style trucks over 10,000

GVWR not equipped with airbrakes to be inspected at a lower cost to the

citizen.

Economic Impact on Small Businesses

The proposed action has a meaningful economic impact on small

businesses. An analysis of this economic impact follows:

Economic Impact on Small Businesses: The proposed action has a

meaningful economic impact on small businesses. As stated in the summary the

revised regulations will have a positive economic impact on small businesses.

The elimination of a previously required tool will save businesses between

$1,500 and $2,500. This also allows for a streamlined, quicker, inspection

process, which may increase their daily earning potential. Lastly, the

availability of digital version of the Vehicle

Inspection Handbook at a reduced cost will have a positive impact.

Impact on Individuals with Disabilities

The proposed action has an impact on individuals with disabilities

as follows:

The proposed action has an impact on individuals with disabilities

as follows: Positive impact, the new regulations have provisions to inspect and

accommodate specialized and/or modified equipment installed in vehicles for

persons with disabilities. Whether it is equipped for disabled passengers and

or disabled drivers. Currently, there are no provisions to accommodate this

equipment, and many times the vehicles must be converted back to a conventional

vehicle for inspection. This is cost-prohibitive.

Opportunity for Public Comment

Comments may be sent to Tracey C. Sheffield, Regulations

Coordinator, MVA, 6601 Ritchie Highway NE, Room 200 Glen Burnie, MD 21062, or

call 410-768-7545, or email to [email protected]. Comments will be

accepted through August 11, 2025. A public hearing has not been scheduled.

11.14.01 General Inspection Requirements

and Provisions

Authority: Transportation Article, §12-104(b), §22-104, §23-101 –

23-109, §24-106.1, and § 25-110

Annotated Code of Maryland

.01 Definitions.

A. In this subtitle, the following terms have the meanings

indicated. . Terms Defined.

(1) “Administration” means the Maryland Motor Vehicle

Administration of the Maryland Department of Transportation.

(2) “Autocycle” means a motor vehicle that:

(a) Has two front wheels

and one rear wheel;

(b) Has a steering wheel;

(c) Has permanent seats

on which the operator or a passenger is not required to sit astride;

(d) Has foot pedals to

control acceleration, braking, and, if applicable, a clutch; and

(e) Is manufactured to

comply with federal safety standards for motorcycles.

(3) “Bed” means the load-carrying part temporarily or

permanently attached to a vehicle and separated from the passenger compartment

and fully enclosed on both sides by sideboards or side panels, on the front by

a board or panel or by the cab of the vehicle, and on the rear, by a tailgate,

board, or panel.

(4) “Commercial motor vehicle” means any self-propelled or towed

motor vehicle used on a highway for interstate or intrastate commerce to

transport passengers or property when the vehicle:

(a) Has a gross vehicle weight rating or gross combination

weight rating, or gross vehicle weight or gross combination weight, of 10,001

pounds (4,536 kg) or more, whichever is greater:

(b) Is designed or used to transport more than eight passengers

(including the driver) for compensation;

(c) Is designed or used to transport more than 15 passengers

(including the driver) and is not used to transport passengers for

compensation; or

(d) Is used in transporting material found by the Secretary of

Transportation to be hazardous under 49 U.S.C. §5103 and transported in a

quantity requiring placarding under regulations required by the Secretary under

49 CFR.

(5) “Conviction” has the meaning stated in Transportation

Article, §11-110, Annotated Code of Maryland.

(6) “Covert vehicle” means a vehicle used by the Division to

monitor compliance with COMAR 11.14, by inspection stations, or inspection

personnel.

(7) “Covert vehicle inspection” means the submission of a covert

vehicle as defined in §B(6) of this regulation to inspection stations, or

inspection personnel, for the investigation of compliance with COMAR 11.14

during inspection, or the presentation of a fictitious safety equipment repair

order.

(8) “Dealer” means a dealer who is licensed in this State under

Transportation Article, Title 15, Annotated Code of Maryland.

(9) “Division” means the Automotive Safety Enforcement Division

(ASED) of the Department of State Police.

(10) “DOT” means United States Department of Transportation.

(11) “Enclosures” means the front, rear, and sides of a vehicle

bed as defined in Transportation Article, §24-106.1(d)(1), Annotated Code of

Maryland.

(12) “Facility” means a vehicle dealer repair shop, vehicle

repair garage, or service station vehicle repair shop.

(13) “Fictitious safety equipment repair order” means a safety

equipment repair order that is an authentic document containing information

that may be fabricated, prepared by Division personnel for submission for

inspection and compliance with COMAR 11.14.

(14) “Fleet station” means an organization, company, business,

educational institution, or municipal facility that owns, operates, or controls

15 or more vehicles, and has been licensed and authorized by the Division to

inspect only those vehicles owned, operated, or controlled by the licensee.

(15) “GVWR” means the gross vehicle weight rating as determined

by the manufacturer.

(16) “Inspection certification” means a certification by an

inspector, in a format established by the Division, that:

(a) Certifies that as of the specified date, and mileage (if

applicable), at the time of certification, a vehicle, identified by the Vehicle

Identification Number (VIN), and having been subject to a vehicle safety

inspection, meets or exceeds the standards established in these regulations;

and

(b) Inspection includes initial inspections, inspection of vehicle

equipment rejected during a previous inspection, or inspection of vehicle

equipment due to the issuance of a safety equipment repair order.

(17) “Inspection station” means a facility that has been

authorized to allow the performance of vehicle safety inspections, the

certification of inspections of compliant vehicles, and the certification of

safety equipment repair orders for a specific class or classes of vehicles.

(18) “Inspector” means an individual who:

(a) Meets the requirements defined in Regulation .04 of this

chapter;

(b) Has passed the appropriate written and demonstrative ability

examinations;

(c) Is not under any type of administrative sanctions; and

(d) Has been licensed as an inspector by the Division to perform

vehicle safety inspections on specific classes of vehicles at a specific type

of inspection station.

(19) “Limousine” means a vehicle that:

(a) Has been modified or stretched for transportation of

passengers;

(b) Is driven as part of a service provided by a person that

advertises itself as a provider of limousine services or registers with the

Public Service Commission as a provider of limousine services; or

(c) Is equipped with additional amenities not normally provided

in passenger cars, for passenger convenience.

(20) “Load cover” means a device made of canvas or other type

material and used to enclose the open top of a vehicle bed, as defined in

Transportation Article, §24-106.1(a), Annotated Code of Maryland.

(21) “Loose material” means loose material as defined in

Transportation Article, §24-106.1(a), Annotated Code of Maryland, and COMAR

11.15.20.01.

(22) “Low-speed vehicle” means a four-wheeled motorized vehicle

that has a maximum speed capability that exceeds 20 miles per hour and not more

than 25 miles per hour on a paved level surface, and whose GVWR is less than

3,000 pounds.

(23) Manufacturer.

(a) “Manufacturer” means a person or entity in the business of

constructing or assembling vehicles of a type required to be registered under

Transportation Article, Title 13, Annotated Code of Maryland.

(b) “Manufacturer” includes a person or entity in the business

of constructing or assembling the first-stage manufacture of an incomplete

vehicle, and the second-stage manufacture of a two-stage vehicle so that it

becomes a completed vehicle, as these terms are defined in Transportation

Article, §13-113.2 Annotated Code of Maryland.

(24) “Maryland Safety Inspection System (MSIS)” means the

electronic reporting and certification system established by the Division to

facilitate the electronic submission of inspection certifications to the

Administration and provide an electronic database of vehicle inspection

records.

(25) “Modular home trailer” means a trailer manufactured solely

for transporting modular homes or portions of modular homes.

(26) “Motorcycle” means a motor vehicle that:

(a) Has motive power;

(b) Has a seat or saddle for the use of the rider;

(c) Is designed to travel:

(i) On not more than three wheels in contact with the ground;

and

(ii) At speeds exceeding 35 miles per hour; and

(d) Complies with all motor vehicle safety standards applicable

to motorcycles under federal law.

(27) “Multipurpose passenger vehicle” means:

(a) A motor vehicle that is designed primarily for carrying

persons which is constructed on a truck chassis or with special features for

occasional off-road operations; or

(b) A motor vehicle that is of unique design that does not meet

the requirements of any other class as determined by the Division, except

4-wheel drive passenger vehicles (sedans, convertibles, and station wagons).

(28) “NHTSA” means National Highway Traffic Safety

Administration.

(29) “OEM” means original equipment manufacturer.

(30) “Physical Disability Medical Exemption for Vehicle

Equipment” means a form issued by the Division to provide notification and

documentation to inspection station personnel performing an inspection of a

vehicle that:

(a) The vehicle has been properly modified and identified, to

enable a person with a disability to operate, or ride as a passenger in the

motor vehicle; and

(b) Is exempted from the “make inoperative” prohibition of 49

U.S.C. §30122 to the extent that those modifications affect the motor vehicle's

compliance with the Federal Motor Vehicle Safety Standards or portions thereof

specified in 49 CFR §595.7.

(31) “Physician’s Written Certification of Necessity for Medical

Exemption from Maryland Window Tint Limitations Form” is a form issued by the

Division that enables a physician to render a signed statement indicating a

person meets all provisions for a medical exemption set forth in Transportation

Article, §22-406, Annotated Code of Maryland, and the applicable COMAR

governing post manufacture window tinting while being operated by the primary

owner/driver.

(32) “Police officer” means:

(a) A uniformed police officer as defined in Transportation

Article, §11-147, Annotated Code of Maryland; or

(b) A civilian employee of the Department of State Police as

defined in Transportation Article §23-101(g), Annotated Code of Maryland.

(33) “Post Manufacture Window Tint Inspection Report” means a

form that:

(a) Has been approved by the Division;

(b) Has been completed by an inspector; and

(c) Identifies the owner or agent, the vehicle information, and

light transmittance readings of regulated windows equipped with post

manufacture window tint.

(34) Post Manufacture

Window Tint Medical Exemption Form”.

(a) “Post Manufacture Window Tint Medical Exemption Form” means

a form issued by the Division upon presentation of a written certification from

a physician or optometrist licensed to practice medicine in the State of

Maryland that details the vehicle owner’s medical need for windows tinted to

less than 35 percent light transmittance.

(b) “Post Manufacture Window Tint

Medical Exemption Form” authorizes an inspector to exempt the vehicle’s windows

equipped with post manufacture window tint from meeting the light transmittance

requirement during a vehicle inspection, or during certification of a SERO

issued to an owner of a vehicle.

(35) “Rebuilding” means the restoring of a salvage vehicle as

set forth in Transportation Article, §13-506, Annotated Code of Maryland, or a

vehicle that is inoperable because of the need for major or extensive repairs

to the body, frame, suspension, engine, or drivetrain.

(36) “SAE” means the Society of Automotive Engineers.

(37) “Safety Equipment Repair Order (SERO)” means a hand-printed

or electronic directive ordering repair of defective equipment on a specified

vehicle.

(38) Second-Stage Manufacturer.

(a) “Second-stage manufacturer” means a licensed second-stage

manufacturer as defined in Transportation Article, §15-201, Annotated Code of

Maryland.

(b) “Second-stage manufacturer” includes a person who works on

an incomplete vehicle so that it becomes a complete vehicle in accordance with

COMAR 11.15.27 and Transportation Article, §15-201, Annotated Code of Maryland,

or retrofits an existing vehicle for dump service registration with the

Administration so that it becomes a complete vehicle in accordance with COMAR

11.15.27 and Transportation Article, §15-201, Annotated Code of Maryland; and

(c) A second-stage manufactured vehicle shall be identified as

such only if the vehicle is labeled in accordance with 49 CFR §567.5.

(39) “Securement hardware” means any device used to attach or

secure a cover on a vehicle bed.

(40) Specially Constructed Vehicle.

(a) “Specially constructed vehicle” means a vehicle that was not

originally constructed under a distinctive name, make, model, or type by a

generally recognized manufacturer of vehicles and has not been materially

altered from its original construction, including kit cars and replicas of

previously manufactured vehicles.

(b) “Specially constructed vehicle” does not include a vehicle

assembled from parts acquired from multiple vehicles or other sources that has

been assembled into a single vehicle, other than one which is constructed upon

an engineered and manufactured kit from a manufacturer as defined in this

regulation.

(41) “State Police” means the Maryland Department of State

Police.

(42) “Supervisor” means an individual who:

(a) Has supervisory authority within the business establishment;

(b) Has been designated by the applicant or licensee, and agrees

to be responsible for the daily operation of the inspection program at the

facility; and

(c) Has submitted a Division application, passed a written

examination administered by the Division, and has been approved by the Division

to act on behalf of a licensee.

(43) “Vehicle” means, except as otherwise provided in this

regulation, any vehicle registered or to be registered in this State as:

(a) Class A (passenger) vehicle;

(b) Class E (truck) vehicle;

(c) Class F (tractor) vehicle;

(d) Class G (trailer) vehicle;

(e) Class J (vanpool) vehicle;

(f) Class M (multipurpose) vehicle;

(g) Class B (for hire) vehicle;

(h) Class D (motorcycle) vehicle;

(i) Class Q (limousine) vehicle; and

(j) Class L (historic) applicable to a historic vehicle sold by

a licensed Maryland dealership, which was previously titled or registered in

another state or country, for initial registration in Maryland:

(i) For the purpose of load covers, required by Transportation

Article, §24-106.1, Annotated Code of Maryland, any vehicle as defined in

Transportation Article, §11-176, Annotated Code of Maryland;

(ii) For the purpose of SERO issuance, a motor vehicle, trailer,

semitrailer, Class L (historic) vehicle with the model year of 1986 or later,

and Class L truck, tractor, and multipurpose motor home over 10,000 GVWR,

except as provided in §B(43)(d) of this regulation; or

(iii) For the purpose of a SERO issuance, “Vehicle” does not

include any Class L (historic) vehicle with the model year of 1985 or earlier,

Class N (street rod) vehicle, or trailer which is a mobile home as defined in

Transportation Article, §11-134, Annotated Code of Maryland.

(44) “Vehicle Inspection Handbook” means a book of regulations

governing motor vehicle inspections, obtained from the Office of the Secretary

of State, Division of State Documents, for the State of Maryland, in a format

approved by the Division.

(45) “Vehicle Safety Inspection Bulletin” means a bulletin

released by the Division to supply an enforceable interpretation of the

regulation, or to provide guidance for procedures related to the vehicle safety

inspection program for specific circumstances not covered by the Vehicle

Inspection Handbook, and to address emerging automotive technical innovation which

may seem to conflict with current regulations.

.02 Administrative Penalties.

A. The inspection station license under Regulation .03 of this

chapter, or the inspector license under Regulation .04 of this chapter, may be

refused, revoked, or suspended if the station or inspector has

committed any of the offenses in this regulation:

(1) Falsification of facts shall result in revocation of the

license to protect the integrity of the Vehicle Safety Inspection Program;

(2) Failure to comply with any requirements of the regulations

contained in COMAR 11.14; or

(3) Materially altering, or knowingly allowing changing of

equipment on a vehicle:

(a) For which an inspection certification or a repair order

certification has been issued, that results in equipment not meeting or

exceeding the standards established under this subtitle; or

(b) For a vehicle registered in Maryland, or sold for

registration in Maryland which results in equipment not meeting or exceeding

the standards established under this subtitle.

B. Corrective action procedures are intended to establish an

equitable and effective process to correct unacceptable vehicle safety

inspection actions. The regulations contained within this chapter establish

corrective actions and administrative penalties through direct reference in the

regulation, or by the penalty assessment categories found in §C of this

regulation.

(1) Vehicle steering systems, suspension systems, brake systems,

and tire and wheel equipment are critical safety equipment systems that may

have a very high potential for loss of control of a vehicle during operation

and shall result in the application of severe penalties for unacceptable

vehicle safety inspection actions:

(a) A school vehicle, as defined in Transportation Article,

§11-154, Annotated Code of Maryland is also regulated for inspection under

COMAR 11.19.04 School Vehicle Inspection by Authority established in

Transportation Article, §§12-104(b) and 25-110, Annotated Code of Maryland.

(b) A school vehicle, due to the specific purpose of safely

transporting children, categorizes and identifies additional vehicle equipment

in this regulation as “School Vehicle Critical Safety Equipment”, and the

Administration may suspend the registration and confiscate the registration

plates of a school vehicle determined to be unfit or unsafe for the

transportation of passengers.

(2) When multiple offenses have been committed, all offenses

will be included in the Investigative Report as supporting documentation to

determine the corrective action to be taken.

(a) A combination of any three or more violations committed

during the same action or inspection will enhance the violation to a higher

category.

(b) Subsequent violations within 12 months enhance the penalty

to a higher category.

(c) Subsequent Category “II”, “III”, or “IV” violations within

12 months of reinstatement into the Inspection Program after a served penalty

will result in enhanced penalties for violations.

(3) All categories of offenses will apply uniformly to the

inspectors involved in the offenses and inspection station alike, where it is

revealed that inspection station supervision was involved in the matter or had

knowledge of its occurrence.

(4) Corrective disciplinary action for each category of offense

shall not be exceeded unless strong mitigating circumstances exist which

require escalation of charges, otherwise, the appropriate corrective action

will be taken.

C. Penalty assessment categories are divided into five groups of